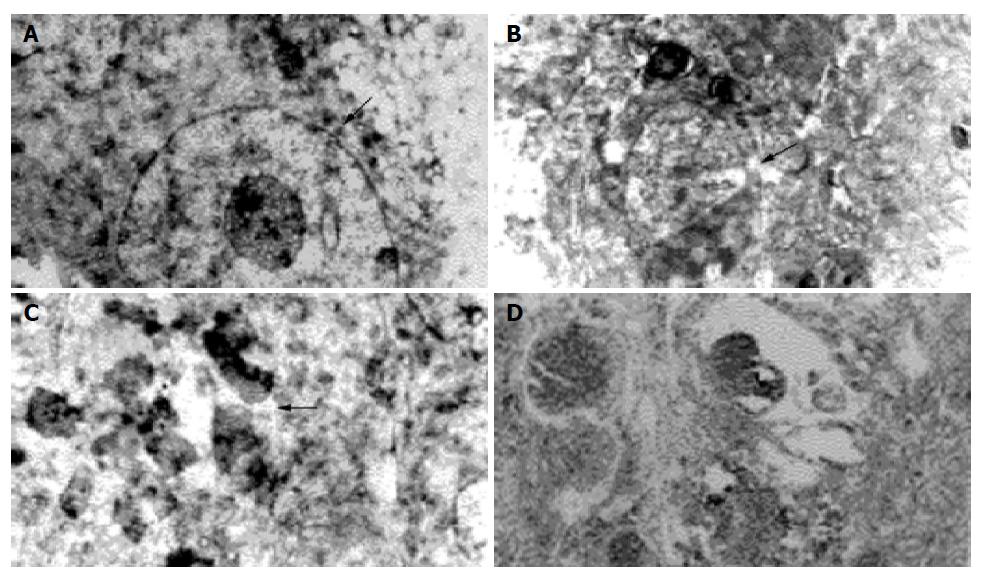

Grossman et al., Thin film oxide barrier layers: protection of Kapton from space environment by liquid phase deposition of titanium oxide. Chen et al., The influence of Cu nanoparticles on the tribological properties of polydopamine/PTFE + Cu films. Lim, Tribological behavior of PTFE film with nanodiamond. Lim, Tribological behavior of PTFE nanomposite films reinforced with carbon nanoparticles. Zou, Wear resistant PTFE/SiO 2 nanoparticle composite films. Bourne et al., Wear resistant solid lubricant coating made from PTFE and epoxy. Björling et al., Effect of humidity and counterface material on the friction and wear of carbon fiber reinforced PTFE composites. Ko, Fabrication of ultrafine fibrous polytetrafluoroethylene porous membranes by electrospinning. Wan et al., Enhanced atomic oxygen resistance and tribological properties of PAI/PTFE composites reinforced by POSS. Chen et al., Quantitative characterization of the transfer film morphology of SiO 2 /PTFE composite. Harris et al., Ultralow wear fluoropolymer composites: nanoscale functionality from microscale fillers. Wang et al., Tribological performance and lubrication mechanism of solid-liquid lubricating materials in high-vacuum and irradiation environment. Lacombe et al., Structural characterization of an electrically insulating diffusion barrier on a plasma-sprayed ceramic for severe environment applications. Luberda-Durnas et al., The nature of interactions and UV-induced response within α-Zirconium phosphate intercalation compounds with azobenzenes. Slamecka et al., Deposition of hydroxyapatite and tricalcium phosphate coatings by suspension plasma spraying: effects of torch speed. Zhou et al., Tribological properties of adaptive phosphate composite coatings with addition of silver and molybdenum disulfide. Chnag et al., Comparison of the crystallization behavior of silica between Mg- and Al-phosphate used in tension coatings of grain-oriented electrical steel. Feng et al., Tribological behavior of molybdenum disulfide bonded solid lubricating coatings cured with organosiloxane-modified phosphate binder. Zhou et al., Preparation and properties of aluminum phosphate/organosilicon resin organic-inorganic hybrid materials and fiber reinforced composites. Ha et al., Development of Cr-free aluminum phosphate binders and their composite applications. Tamaki et al., Carbon fiber/ceramic composite using aluminum phosphate with different P/Al molar ratios. Chung, Acid aluminum phosphate for the binding and coating of materials. Shen et al., Robust superhydrophobic attapulgite meshes for effective separation of water-in-oil emulsions. Yuan et al., Robust waterborne superhydrophobic coatings with reinforced composite interfaces. Li et al., Inorganic adhesives for robust, self-healing, superhydrophobic surfaces. Thus, this study is expected to provide a new idea for designing and applying self-lubrication coating materials in extreme space environments. These are due to a continuous phosphate binder phase itself had a good resistance to AO irradiation. Results indicated that PTFE molecules embedded into the phosphate networks homogeneously could not only improve the flexibility of the coatings from grade 3 to 1 but also exhibit excellent friction and wear properties under air and vacuum conditions after a long-term AO irradiation.

The influence of atomic oxygen (AO) irradiation on microstructure and tribological properties of the coatings were then investigated. This paper aims to provide a new way to improve the flexibility of phosphate coating by using polytetrafluoroethylene (PTFE) as the dopant. Inorganic phosphate coating exhibits great potential applications in extreme environments, it is regrettable that its poor mechanical flexibility limited their scope of application.

0 kommentar(er)

0 kommentar(er)